310 Stainless Steel Channel

310 Stainless Steel Channel

Contact form

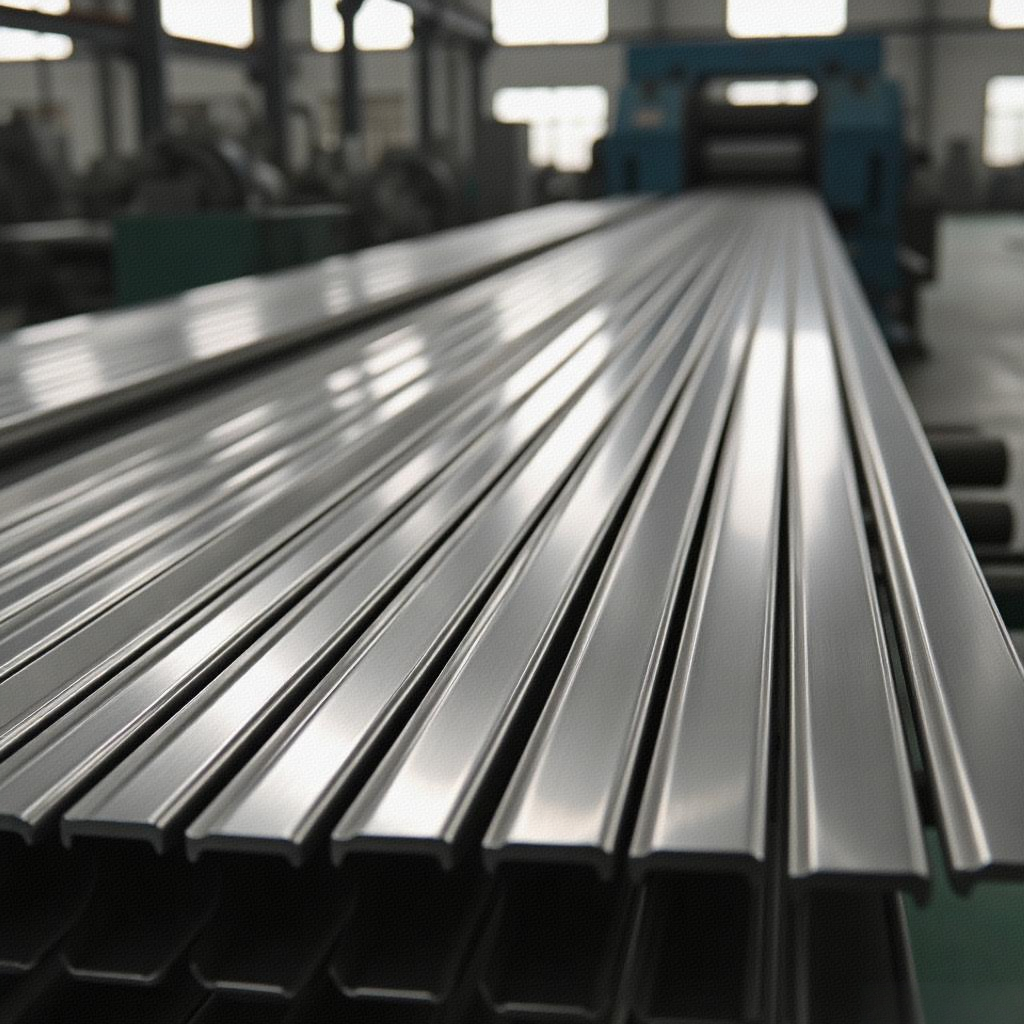

High-Temperature 310 Stainless Steel Channel: Premium Solutions for Extreme Industrial Applications

For industries requiring unparalleled resistance to extreme heat, corrosion, and mechanical stress, the 310 stainless steel channel stands as a superior choice. With its high chromium (25%) and nickel (20%) content, this alloy outperforms standard grades like 304/316 in temperatures exceeding 2100°F (1150°C). Available in stainless steel channel sizes from 1"x1" to 8"x4", and customizable stainless steel u channel sizes, this product is engineered for critical applications in furnaces, aerospace, and chemical processing. Below, we dive into its technical specifications, industry-specific uses, and SEO-optimized insights to enhance your purchasing decision.

Technical Specifications: Engineered for Extreme Performance

| Category | Details |

|---|---|

| Material Composition | 310 Stainless Steel: 25% Cr, 20% Ni, 1.5% Mn, 0.25% C. Compliant with ASTM A276 and ASME SB-409 for high-temperature stability. |

| Dimensions & Sizes | Standard Sizes: 1"x1" to 8"x4" (height x width). Custom stainless steel u channel sizes up to 12"x6" available for specialized projects. Tolerance: ±0.5mm. |

| Thickness & Durability | 1mm (thin-walled ducts) to 20mm (heavy-duty structural supports). Ideal for thermal expansion management in cyclic environments. |

| Surface Finishes | Mill Finish (as-rolled), Brushed Stainless Steel U Channel (anti-glare, Ra 0.4 µm), Mirror Polish (for aesthetic appeal), Heat-Treated (scaling resistance). |

| Certifications | ISO 9001, RoHS, NACE MR-0175. Mill Test Certificates (MTC) with full traceability and chemical analysis. |

Why 310 Stainless Steel Outperforms Competitors

- Unmatched Heat Resistance: Retains structural integrity at 2100°F (1150°C), making it ideal for furnace trays, radiant tubes, and burner nozzles.

- Corrosion Resilience: Resists sulfidation in oil refineries and carburization in heat treatment plants, ensuring longevity in harsh environments.

- Mechanical Strength: Tensile strength of 600 MPa and hardness of 200-250 HV prevent deformation under heavy loads or thermal stress.

Applications & Customization: Industry-Driven Solutions

| Industry | SEO-Optimized Applications |

|---|---|

| Industrial Furnaces | 310 stainless steel channel used for radiant coils, quenching racks, and annealing fixtures due to oxidation resistance. |

| Aerospace & Defense | Combustion chamber liners and exhaust systems requiring stainless steel u channel sizes with creep resistance at 1800°F+. |

| Petrochemical Plants | Reactor supports, catalyst grids, and flare stacks exposed to H₂S and chlorides. |

| Architecture & Design | Brushed stainless steel u channel finishes for fire-rated façades, elevator shafts, and decorative heat-resistant trims. |

| Energy Production | Boiler components, nuclear reactor casings, and exhaust ducts built to custom stainless steel channel sizes. |

Advanced Fabrication Services

- Precision Cutting: Laser/plasma cutting for stainless steel u channel sizes with ±0.2mm accuracy.

- Hot Forming: Shape channels into tight radii (3x material thickness) without cracking.

- Surface Customization: Brushed stainless steel u channel textures reduce maintenance in high-traffic areas.

- Welding Expertise: TIG welding with ER310 filler rods for joints matching base metal strength.

Bulk Order Advantages & Fast Global Delivery

Maximize cost efficiency with volume-based discounts:

- MOQ Flexibility: 300 kg minimum, with mixed stainless steel channel sizes and finishes accepted.

- Tiered Pricing: Save 10% on orders over 2 tons; 15% for 5+ tons.

- Rapid Turnaround: 15–20 days for custom brushed stainless steel u channel orders; 7 days for standard stock.

Quality Assurance & Logistics

- Testing: Salt spray (ASTM B117), cyclic oxidation (ASTM G54), and XRF alloy verification.

- Packaging: VCI film + wooden crates to prevent corrosion during transit.

- Global Reach: Shipped from ISO-certified stainless steel channel manufacturers via DHL, FedEx, or sea freight.

SEO-Optimized FAQs

Q: What makes 310 stainless steel channel better for high-heat applications than 316?

A: The 310 stainless steel channel contains 25% chromium and 20% nickel, enabling 2x higher oxidation resistance above 1500°F compared to 316’s 16% Cr/10% Ni.

Q: Can I order non-standard stainless steel u channel sizes for unique projects?

A: Absolutely! We specialize in custom stainless steel u channel sizes up to 12"x6", tailored to your blueprints with CNC precision.

Q: How does a brushed stainless steel u channel finish improve performance?

A: The brushed stainless steel u channel surface minimizes scratches, resists fingerprints, and enhances corrosion protection in humid or acidic environments.

Why Choose Our 310 Stainless Steel Channel?

- Decades of Expertise: Trusted by Siemens, GE, and leading furnace manufacturers.

- Eco-Friendly Production: 85% recycled content and RoHS-compliant finishes.

- Digital Tools: Instant quoting platform + 3D CAD file compatibility for seamless integration.

Upgrade your high-temperature systems with premium 310 stainless steel channel solutions. Whether you need standard stainless steel channel sizes or a custom brushed stainless steel u channel, our products deliver unmatched durability, compliance, and ROI. [Request a Quote] today and leverage our expertise to meet your project’s most demanding requirements!