What is the best way to weld stainless steel?

Share

Table of Contents

- Why welding stainless steel is different

- What tools do you need?

- Cleaning is half the battle

- Choosing the right welding method

- TIG Welding (Best for beginners and clean finish)

- MIG Welding (Faster and easier)

- Stick Welding (Good for outdoor or big jobs)

- Practice makes perfect

- Watch your heat!

- Don't forget post-weld cleanup

- A note about safety

- Common mistakes to avoid

- What kind of stainless steel is best for welding?

- Final thoughts

Why welding stainless steel is different

First, let’s understand why stainless steel is a bit tricky. It’s not like regular steel. The reason people love stainless steel is because it doesn’t rust easily, it’s strong, and it looks good. But those same qualities also mean it reacts differently when heated.

When you weld stainless steel, the heat can mess up its surface, change its color, or make it more likely to rust at the welded spot if you’re not careful. That’s why it’s important to use the right technique from the start.

What tools do you need?

You don’t need a fancy workshop or super expensive gear. Here’s a simple list of what you’ll need:

- A welding machine (most people use TIG or MIG for stainless steel)

- Stainless steel filler rods

- Safety gear (gloves, helmet, long sleeves)

- A clean workspace with good airflow

- Wire brush or grinder (to clean the metal before welding)

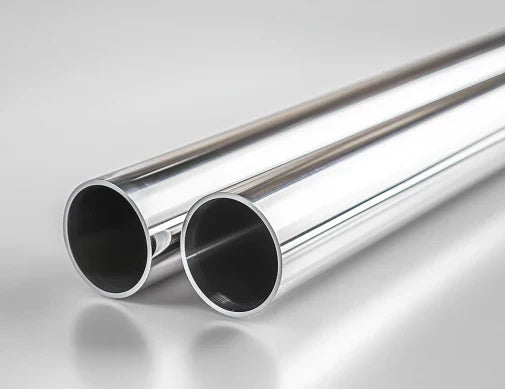

Make sure you also get your materials from trusted steel Suppliers, because the quality of your stainless steel bar really matters. If you're using something like a 5 316/316L Stainless Steel Bar, you’re starting with top-grade material that’s known for its corrosion resistance and strength.

Cleaning is half the battle

Before you even start welding, make sure the metal is clean. Stainless steel can pick up dirt, oil, or even small pieces of other metals. If you weld it while it’s dirty, you’re just asking for trouble.

Use a wire brush or a grinder to clean the area where you’re going to weld. Just make sure the tools you use are only for stainless steel—don’t mix them with tools used on other metals, or you could contaminate the surface.

Choosing the right welding method

Okay, here’s where many people get stuck. There are different ways to weld stainless steel, but don’t let that overwhelm you. The most common ones are TIG, MIG, and stick welding. Let’s break them down in simple terms:

1. TIG Welding (Best for beginners and clean finish)

TIG welding (Tungsten Inert Gas) is like using a tiny flame to melt the metal. It’s clean, controlled, and perfect for small or delicate jobs. If you're working on a visible part of a project—like a railing or countertop—this method gives you the cleanest finish.

Pros:

- Super clean welds

- Great control

- Works well with thin stainless steel

Cons:

- Takes longer

- Requires a steady hand

TIG welding works really well on 5 316/316L Stainless Steel Bar because it allows for precision and avoids overheating the material.

2. MIG Welding (Faster and easier)

MIG welding (Metal Inert Gas) is more forgiving and faster. You feed a wire through the gun, and it melts into the joint. It’s good for thicker stainless steel bar or when you're not worried about looks.

Pros:

- Faster

- Easier to learn

- Good for thicker metal

Cons:

- Not as neat as TIG

- More spatter (metal splashes around a bit)

3. Stick Welding (Good for outdoor or big jobs)

Stick welding is old-school but reliable. It’s not as clean or easy as TIG or MIG, but it works, especially when you're working outside or on larger pieces.

Pros:

- No need for gas tanks

- Works outside, even in wind

Cons:

- Messier finish

- Not great for thin material

Practice makes perfect

If you’ve never welded before, don’t start on your final project. Get a few scrap pieces of stainless steel bar and practice first. Try different speeds, angles, and settings on your welder. You’ll start to see what works and what doesn’t.

And don’t get discouraged if it doesn’t look perfect right away—welding is a skill. Even seasoned welders make mistakes.

Watch your heat!

Here’s something really important: stainless steel doesn’t like too much heat. If you overheat it, it can change color, lose its anti-rust ability, or even warp. Keep your welds short and controlled. Let things cool off in between if needed.

This is especially important when welding high-quality materials like a 5 316/316L Stainless Steel Bar. You want to keep that corrosion resistance intact.

Don't forget post-weld cleanup

Once you're done welding, don’t just walk away. The area around the weld might be discolored or even have small metal splatters. Use a stainless steel wire brush to clean things up. You can also use special cleaning sprays or gels to bring back that shiny look.

This post-cleaning is more than just for looks—it helps prevent rust and keeps your project strong over time.

A note about safety

Welding can be dangerous if you're not careful. Always wear a proper welding helmet, gloves, and long sleeves. Make sure your workspace has good airflow, and never weld near anything flammable.

Also, try not to breathe in any of the fumes. If you're working inside, use a fan or open a window.

Common mistakes to avoid

Let’s go over a few things that trip people up:

- Welding dirty metal – Always clean the metal first.

- Too much heat – It can ruin the steel.

- Wrong filler rod – Make sure it matches your base metal.

- No post-cleaning – Skipping this step can cause rust later.

- Using the wrong tools – Only use stainless-compatible brushes and grinders.

If you avoid these, your welds will be stronger, cleaner, and longer-lasting.

What kind of stainless steel is best for welding?

Not all stainless steels are the same. Some are easier to weld than others. 316/316L stainless steel, for example, is a favorite because it’s strong and very resistant to rust, even around saltwater or chemicals.

That’s why steel Suppliers often recommend 5 316/316L Stainless Steel Bar for projects that need both strength and corrosion resistance. It’s a solid choice for marine use, kitchens, and even chemical factories.

If you’re buying from reputable steel Suppliers, they can usually point you in the right direction for what type of stainless steel bar to use.

Final thoughts

So, what’s the best way to weld stainless steel?

It depends on what you're doing, but in general:

- Use TIG welding if you want a clean, precise job

- Use MIG welding for faster, thicker welds

- Always clean your materials before and after welding

- Don’t overheat the metal

- Practice a few times before starting your real project

Start with good materials, like a 5 316/316L Stainless Steel Bar, get them from trusted steel Suppliers, and take your time learning. Once you get the hang of it, you’ll be amazed at what you can build and fix with stainless steel.